When it comes to lifting heavy loads in industrial settings, choosing the right type of sling is crucial. Two common options are round slings and flat webbing slings, but what sets them apart? Let's explore the key differences between these two types of lifting slings.

Construction

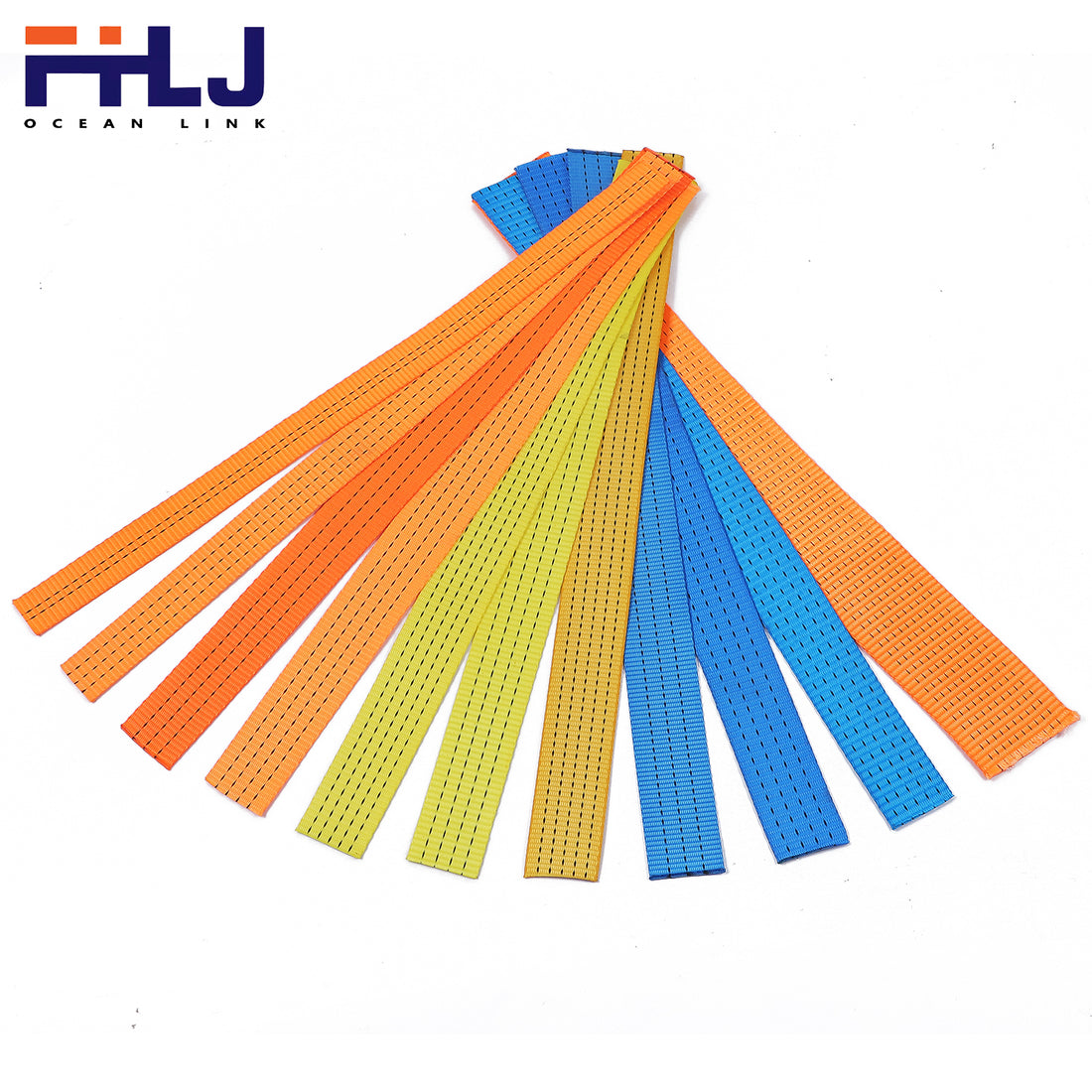

Round slings are made of a continuous loop of synthetic material, such as polyester, that is encased in a protective sleeve. This design allows the load to be cradled securely without causing damage. On the other hand, flat webbing slings are constructed from a flat piece of webbing material, typically made of polyester or nylon, that is stitched together to form a loop.

Flexibility

Round slings are known for their flexibility, making them ideal for lifting loads with irregular shapes or delicate surfaces. The soft, pliable material conforms to the shape of the load, providing a secure grip without causing damage. Flat webbing slings, while still flexible, may not offer the same level of conformity as round slings.

Strength

Both round slings and flat webbing slings are designed to handle heavy loads, but their strength may vary. Round slings are often rated for higher working load limits compared to flat webbing slings of the same size. This is due to the construction of round slings, which distributes the load evenly across the entire sling.

Durability

Round slings are known for their durability and resistance to abrasion, making them a long-lasting option for lifting operations. The protective sleeve helps prevent damage to the inner core of the sling, extending its lifespan. Flat webbing slings, while durable, may be more prone to wear and tear over time, especially if used in harsh environments.

In conclusion, the choice between a round sling and a flat webbing sling ultimately depends on the specific lifting application. Round slings offer flexibility, strength, and durability, making them a versatile option for a wide range of lifting tasks. Flat webbing slings, while still effective, may be better suited for simpler lifting operations where flexibility is less of a concern. By understanding the differences between these two types of slings, you can make an informed decision when selecting the right lifting equipment for your needs.

When it comes to lifting heavy loads in industrial settings, choosing the right type of sling is crucial. Two common options are round slings and flat webbing slings, but what sets them apart? Let's explore the key differences between these two types of lifting slings.

Construction

Round slings are made of a continuous loop of synthetic material, such as polyester, that is encased in a protective sleeve. This design allows the load to be cradled securely without causing damage. On the other hand, flat webbing slings are constructed from a flat piece of webbing material, typically made of polyester or nylon, that is stitched together to form a loop.

Flexibility

Round slings are known for their flexibility, making them ideal for lifting loads with irregular shapes or delicate surfaces. The soft, pliable material conforms to the shape of the load, providing a secure grip without causing damage. Flat webbing slings, while still flexible, may not offer the same level of conformity as round slings.

Strength

Both round slings and flat webbing slings are designed to handle heavy loads, but their strength may vary. Round slings are often rated for higher working load limits compared to flat webbing slings of the same size. This is due to the construction of round slings, which distributes the load evenly across the entire sling.

Durability

Round slings are known for their durability and resistance to abrasion, making them a long-lasting option for lifting operations. The protective sleeve helps prevent damage to the inner core of the sling, extending its lifespan. Flat webbing slings, while durable, may be more prone to wear and tear over time, especially if used in harsh environments.

In conclusion, the choice between a round sling and a flat webbing sling ultimately depends on the specific lifting application. Round slings offer flexibility, strength, and durability, making them a versatile option for a wide range of lifting tasks. Flat webbing slings, while still effective, may be better suited for simpler lifting operations where flexibility is less of a concern. By understanding the differences between these two types of slings, you can make an informed decision when selecting the right lifting equipment for your needs.